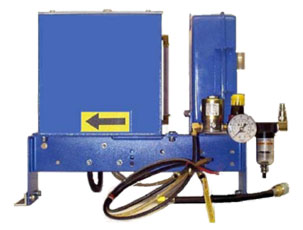

Air Operated Oilers

The OP-4A air operated oilers are pneumatically powered and electrically timed. A caterpillar chain assembly engages the conveyor chain, engaging the oil dispensing nozzle plate, moving it over the chain pin links. An air operated pump meters a precise amount of oil through each nozzle, lubricating chain pins and links simultaneously. The optional 1000 hour repeat cycle timer features cycle progress display and memory.

- The OP-4A system lubricates chain pins while conveyor is running under normal conditions.

- Automatically deposits a clean, metered shot of oil directly and precisely to chain pins at desired intervals. No waste or mess from over oiling.

- Proper lubrication reduces friction and wear – extends conveyor life.

- Fast payback based on reduced maintenance and extended productive conveyor life.

- Eliminates surging caused by non-lubricated and worn chains, so product can be spaced closer, increasing productivity.

- Helps reduce drive power requirements.

Simple, yet effective and clean lubrication for overhead enclosed track conveyors.

- The OP-41A system lubricates chain pins and wheels while the conveyor is running under normal conditions

- Reduces downtime and manual labor operations in lubricating conveyor chain

- Properly lubricated conveyor can extend the life of conveyor components

- Eliminates surging caused by non-lubricated and worn chain and wheels, so product can be spaced closer, increasing productivity

- Conveyor runs smoother, keeps product from swaying, reducing possibility of injury on the line

- Helps reduce drive power requirements

- Less waste and contamination. A metered amount of lubricant is cleanly and precisely delivered to the chain and wheels

- The right lubrication system results in a clean operation — and saves you substantial amounts of time, work and money

The only system specifically designed for high-speed beverage can pin chain conveyors. Designed to eliminate the variables that plague other units, the OPCO ChainMaster OP-54A’s continuous operation provides consistent, even lubrication. The unit precisely applies a thin film of lubricant directly to the chain and provides a coating to the side links to help minimize varnish buildup and keep the chain clean.

- Non-contact system lubricates small pitch chains regardless of speed

- Continuous, even lubrication extends chain life

- Positive displacement pump delivers a metered volume of lubricant

- Large integral reservoir reduces labor time spent refilling

- Instantaneous start-up and shutdown protects operating chains

- Lubricant coating on chain side links decreases varnish and other contaminant buildup

- Ultra-precise spray minimizes over-spray and lubricant waste

- Advanced design reduces chain stretch due to premature wear

- Floor-level reservoir and controls offer easy programming and refilling

- Adjustable volume prevents over-or under- lubrication

Simple, yet effective clean precision lubrication for all types of conveyor systems

- Integral heavy duty 5-gallon steel reservoir

- Lubricant level sight gauge

- Positive displacement metering pump

- Up to 12 individual lubricant outlets

- Proximity sensor or air operated trip device

- Extends the “useful operating life“ of conveyor components and systems

- Lubricates during production

- Reduces maintenance costs

- Reduces conveyor downtime

- Reduces power consumption

- Precision lubrication reduces waste and contamination

- Eliminates conveyor surge

- Reduces undesirable noise

- Wide viscosity range capability provides flexibility in lubricant selection

A lubrication system specifically designed for conveyors used in meat processing. Designed with the meat processing industry’s needs in mind, each lubricator comes with a manual on-automatic off, push button reset timer, which allows easy lubrication after wash-downs. The factory custom sets the chain drop to the customer’s application for precise and cost-effective lubricant application.

- Integral heavy duty 5-gallon steel reservoir

- Lubricant level sight gauge

- Lubricates chain pins during operation

- Positive displacement metering pump

- Lube cycle controller

- Eliminates conveyor surge and prevents rusting/corrosion from wash-downs

- Wide viscosity range capability provides flexibility in lubricant selection

- Can dispense OPCO’s WearMaster lubricants, which are engineered to cover a broad spectrum of applications, including food-handling