Conveyor Trolley Yoke Cleaning Brush

Model #30Y for 3″ I-Beam

Model #40Y for 4″ & 6″ I-Beam

The channel sweeps are designed to remove dirt and debris from the internal conveyor track surfaces. This improves grounding and helps reduce part rejects. These brush assemblies are easily installed by replacing a single chain link. We recommend installing one channel cleaner every 250 feet of chain.

RW91 Replacement brushes

Brass 91312RB

Stainless Steel 91316RB

The channel sweeps are designed to remove dirt and debris from the internal conveyor track surfaces. This improves grounding and helps reduce part rejects. These brush assemblies are easily installed by replacing a single chain link. We recommend installing one channel cleaner every 250 feet of chain.

UN91 Replacement Brushes

Brass 91302RB

Stainless Steel 913BRTB

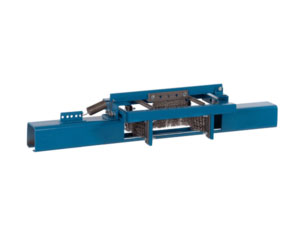

These conveyor cleaning brush assemblies remove dirt and debris from enclosed track conveyor chains. The units come pre-mounted on a modified rail section.

Replacement brushes for 8075-B

Crimped Carbon Steel

Top – 75RB (1)

Sides – 50RB (4)

These conveyor cleaning brush assemblies remove dirt and debris from enclosed track conveyor chains. The units come pre-mounted on a modified rail section.

Replacement brushes for 8074-B

Crimped Carbon Steel

Top – 75RB (1)

Sides – 50RB (4)

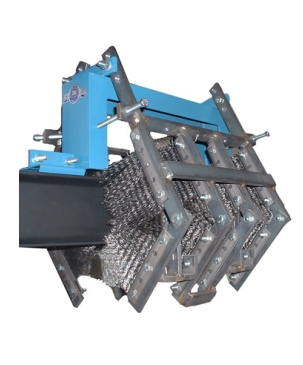

Cleaning the chain and bearing surfaces will help eliminate part rejects, prolong the life of your chain, achieve better grounding, increase the performance of your line, and improve lubricant effectiveness! Mighty Lube offers Beam Sweep Brushes in 3″, 4″, and 6” sizes. Ease of installation and removal makes replacing brushes a quick operation, keeping downtime to a minimum. Not only will the removal of debris and accumulated deposits greatly reduce or even eliminate reject parts, but it allows the lubrication system to perform more efficiently, reducing contamination by lubricant as well as debris.

Model #3-91BC for 3″ I-Beam

Model #4-91BC for 4″ I-Beam

Model #6-91BC for 6″ I-Beam

Replacement brushes for #3-91BC

Stainless Steel

Sides – #913BRS (2)

Top/Bottom – #913BRTB (4)

Replacement brushes for #4-91BC

Stainless Steel

Sides – #914BRS (2)

Top/Bottom – #914BRTB (4)

Replacement brushes for #6-91BC

Stainless Steel

Sides – #916BRS (2)

Top/Bottom – #916BRTB (4)

Download Model 3-91BC Instructions

The I-beam yoke cleaning brush removes buildup from hard to reach, often overlooked sources of contamination. Install by welding the mounting block to the bottom of your conveyor rail.

Model #30Y for 3″ I-Beam

Model #40Y for 4″ & 6″ I-Beam

Replacement brushes for #30Y

Stainless Steel

#30RB (1)

Replacement brushes for #40Y

Stainless Steel

#40RB (1)

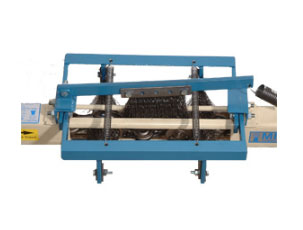

These I-beam chain and trolley cleaners are easy to install. The brush clamps on top of I-beam and there is no welding required.

Chain & Trolley Brush Cleaner With Crimped Steel Brushes

Model #300-I for 3″ I-Beam

Model #400-I for 4″ I-Beam

Model #600-I for 6″ I-Beam

Chain & Trolley Brush Cleaner With Long-Life, Carbide-Impregnated Nylon Brushes

Model #300-INB for 3″ I-Beam

Model #400-INB for 4″ I-Beam

Model #600-INB for 6″ I-Beam

Replacement brushes for #300-I, #400-I, #600-I

Crimped Carbon Steel

#75RB (20)

Replacement brushes for #300-INB, #400-INB, #600-INB

Long-Life, Carbide-Impregnated Nylon Brushes

#75NRB (20)

This is also known as the part saver brush because it prevents contamination of parts by lubricant overspray. This brush assembly mounts on the conveyor at the location of the lubricator.

Model 800QCB

Available for most conveyor types

800QCB Replacement Brushes

91006RB (2)