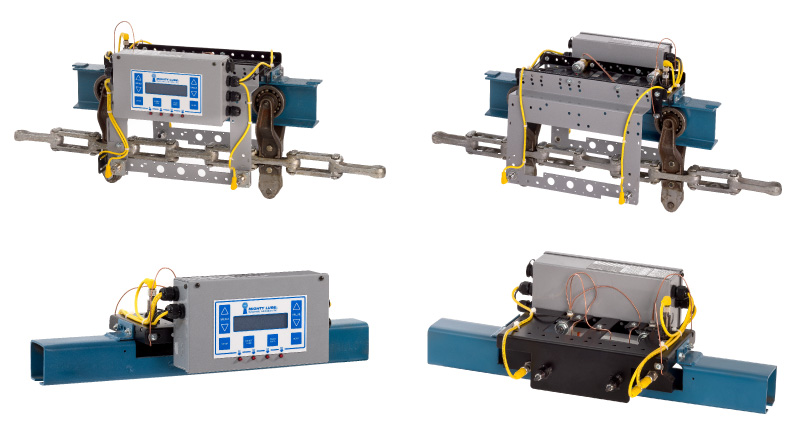

Introducing our new and improved Next Generation Permanent Conveyor Monitoring System. Utilizing our proven technology and expertise, we have expanded the networked monitoring system that our customers have come to rely on.

We still provide the most reliable chain wear data and projections. With this system, you can measure chain wear in both Link by Link and 10’ sections as well as monitoring drive amps, chain speed, take-up pressure and drive hours. This permanent conveyor monitoring system also provides data on lube cycles, reservoir levels, head voltage and pump cycles when combined with a Mighty Lube or OPCO lubrication systems.