Conveyor Brush Cleaners (Powered)

OP – 8 POWERED CONVEYOR CHAIN AND TROLLEY WHEEL CLEANER

Reduces downtime while it cleans your conveyor system. Cleans chain, trolley wheels and trolley brackets. Fits every size of overhead monorail or power & free conveyor.

- Automatically cleans while conveyor is in operation

- Eliminates expensive, time-consuming manual cleaning

- Removes dirt, rust, scale, paint, and/or chemical residue

- Brushes shaped for your conveyor, for efficient operation

- Brush tension can be adjusted while conveyor is running

- Reduces drag on drive motors, extending life

- Proper grounding for electrostatic finishing

- Plated hardware provides longer component life

- Compact, rugged cleaner is easy to install and service

- Overhead, inverted and floor conveyors

OP – 8 WD Conveyor Chain and Trolley Wheel Cleaner

Designed for applications where moisture and humidity is prevalent, due to sanitary wash-downs or exposure to manufacturing processes, the OP-8 Wash-Down Duty Conveyor Chain & Trolley Wheel Cleaner reduces downtime while it cleans your conveyor system. Cleans chain, trolley wheels and trolley brackets. Fits all sizes of overhead monorail or power & free conveyors, and drop finger slider conveyors.

- Automatically cleans while conveyor is in operation

- Eliminates expensive, time-consuming manual cleaning

- Removes process build-up, dirt, rust, scale, and/or paint

- Stainless steel hardware provides long life in moist conditions

- 2HP 230/460vac TEFC 3-phase motor p efficient operation

- Wash-down duty brush shaft bearings and wash-down duty electric motor for long life in moist conditions

- Brushes shaped for your conveyor, for efficient operation

- Split brush shafts for easy, one-bolt removal of each brush assembly. Replacement brushes can be purchased assembled for one-bolt installation of each side.

- Brush tension can be adjusted while conveyor is in operation

- Reduces drag on drive motors, extending life

- Compact, rugged cleaner is easy to install

- Overhead, drop finger, inverted and floor conveyors

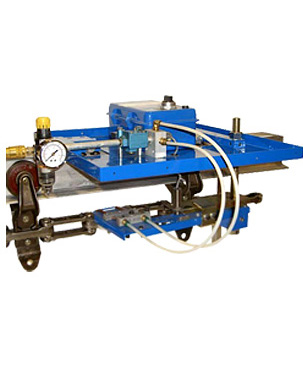

OP – 55 Pneumatic Chain Pin Cleaner

The OP-55 Pneumatic Chain Pin Cleaner is an effective and low-cost cleaning system for Overhead and Inverted Rivetless Chain applications.

- The simple and reliable Precision Arm positions the cleaning nozzles in the critical and hard-to-reach

chain wear areas where dirt build-up can occur - Non-contact positive switching sensor

- Clamp-on mounting feature for overhead system installation; no welding required

- Can be interfaced with existing or anticipated conveyor maintenance equipment

- Three (3) position selector switch with manual override

- 36 in long Neoprene rubber curtain for improved safety and easier housekeeping (easily cut to fit specific needs)